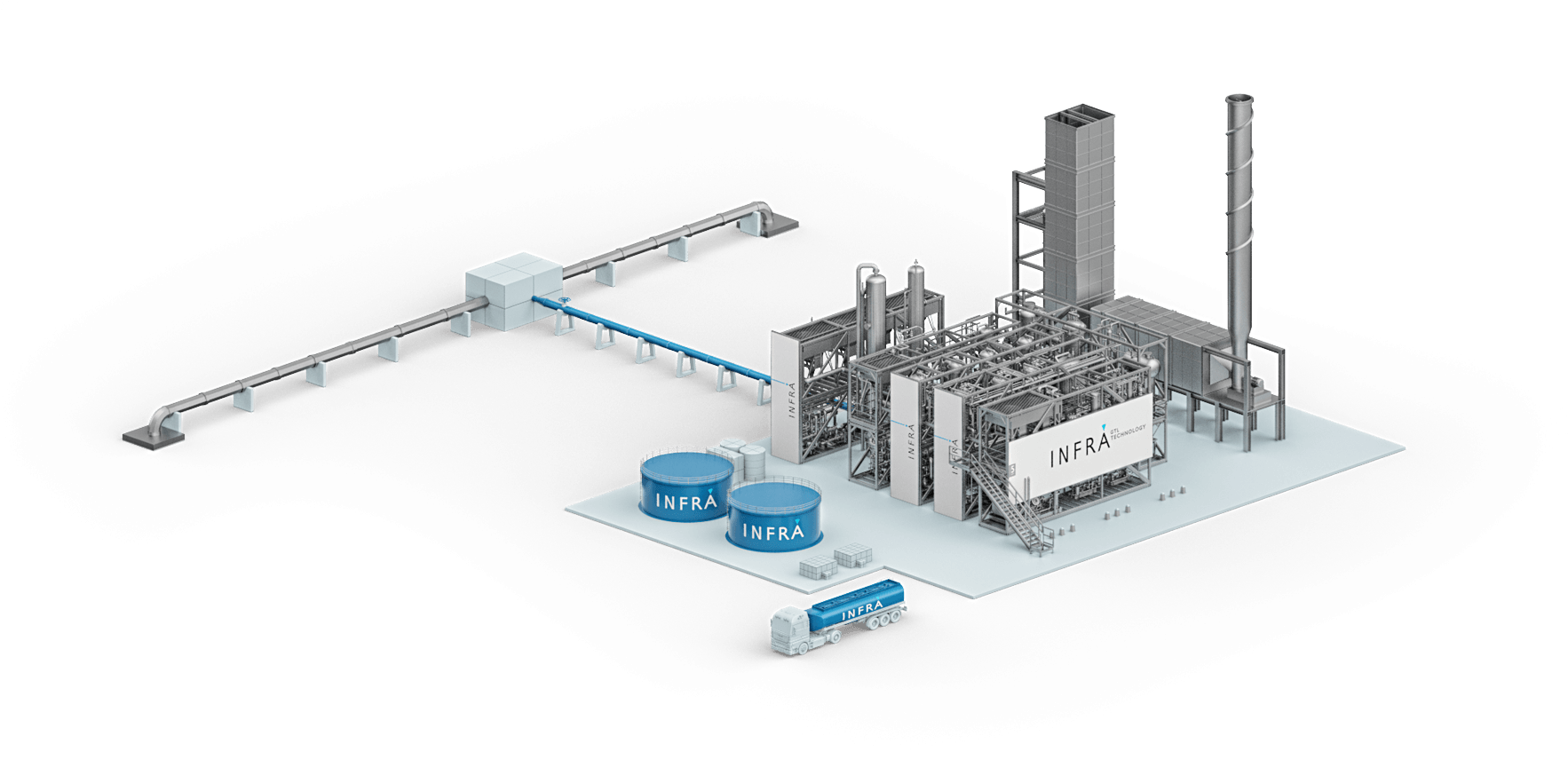

Small-scale GTL

INFRA’s technology can be used in small-scale modular transportable gas-to-liquids units based on the direct conversion of natural gas into synthetic oil, in particular, for the utilization of associated petroleum gas or distributed bio-resources.

Product

Light synthetic oil with unique quality characteristics:

- More than 95% of liquid light fractions (FBP <360 °C).

- No sulphur and aromatics.

- Large fraction of iso-paraffins and olefins.

- High (up to 70) cetane number for diesel fuel.

- Large (up to 45%) of jet fuel fraction.

INFRA’s process allows to produce 1 barrel of synthetic oil (60/40 mixture of gasoline and diesel fractions with high share of jet fuel) per 10,000 cubic feet of gas (methane equivalent).

INFRA’s Gas-To-Liquid products are fully compatible with the existing oil industry infrastructure, processes and technologies and with the existing fleet of transportation vehicles. Its premium synthetic fuels correspond to the highest ecological requirements: zero aromatics, zero sulphur, zero nitrogen, etc. INFRA’s synthetic oil easily mixes and can be transported with mineral oil.

| Technical Information | |

|---|---|

| Feedstock requirements |

|

| Typical Scope of Supply |

|

| Add-on Options |

|

| Key Features |

|

| Key benefits |

|