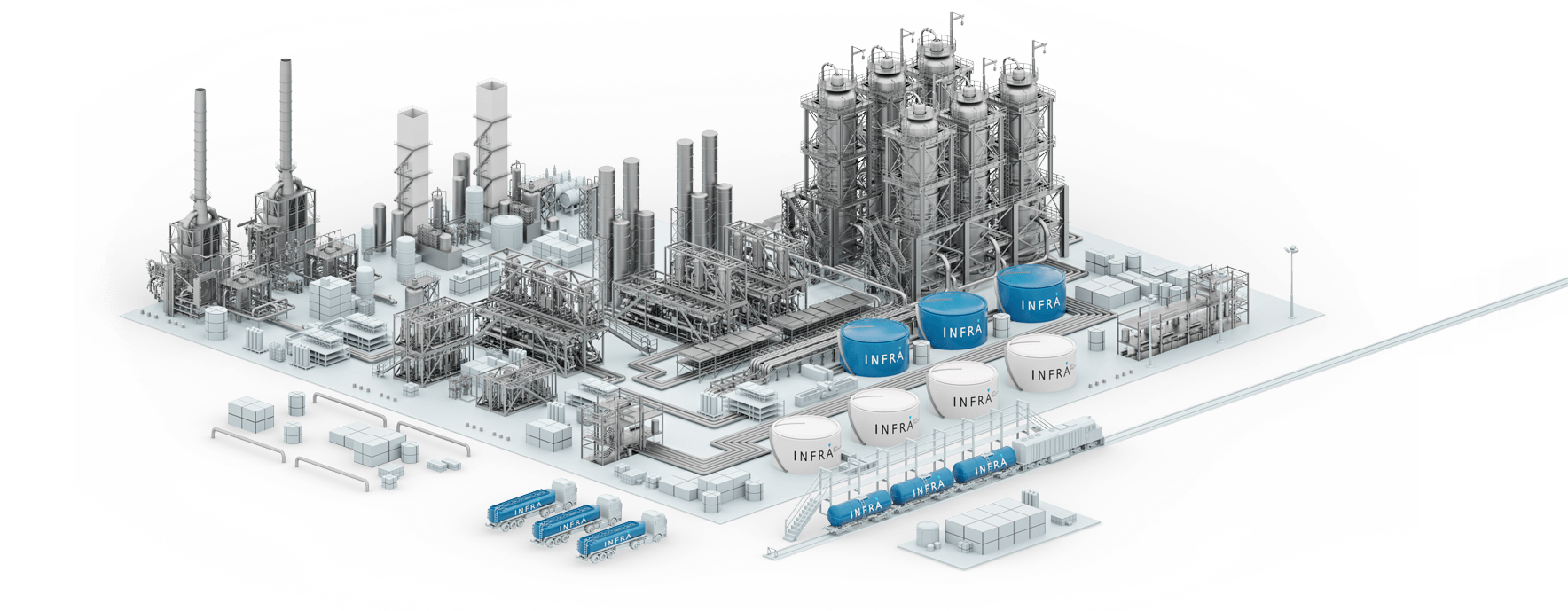

Large-scale GTL

INFRA GTL reduces capital and process operating costs several fold, making GTL/XTL technology not only

economically viable, but cost competitive with oil refining, thus bringing natural gas and coal resources to the crude

oil and transportation fuels markets. Technology offers significant economies of scale.

INFRA is a Fischer-Tropsch technology licensor and patented catalyst supplier for the GTL projects, and provides further assistance and advice to the client’s EPC company during the client’s project execution.

Product

Light synthetic oil with unique quality characteristics:

- More than 95% of liquid light fractions (FBP <360 °C).

- No sulphur and aromatics.

- Large fraction of iso-paraffins and olefins.

- High (up to 70) cetane number for diesel fuel.

- Large (up to 45%) of jet fuel fraction.

For a range of GTL plants, INFRA provides:

- Basic design;

- Proprietary Fischer-Tropsch catalyst supply;

- Fischer-Tropsch block design;

- Catalyst replacement;

- Personnel training.

INFRA’s Gas-To-Liquid products are fully compatible with the existing oil industry infrastructure, processes and technologies and with the existing fleet of transportation vehicles. Its premium synthetic fuels correspond to the highest ecological requirements: zero aromatics, zero sulphur, zero nitrogen, etc. INFRA’s synthetic oil easily mixes and can be transported with mineral oil.

Key benefits

- Low CAPEX and OPEX.

- Produce high quality single liquid product – synthetic crude (no heavy waxes) which does not require hydrocracking and upgrading, and mixes well with crude oil.

- Stable product. No by-products.

- Synthetic crude is fully compatible with the existing oil infrastructure and is easily upgradable to diesel.

- Processes feed gas with varying density.

- Handles CO2 rich gas (up to 25% in feed increases the productivity).

- No requirements for NGL & nitrogen removal from feed gas.

- High carbon efficiency.

- Modular, compact and movable containerized design.

- Electricity generation block.

- Water capture and recycle block.

- Drop-in fuel production e.g., diesel.

- Self-sustained process (no-grid electricity and no fresh water required).

- No requirement for continuous flaring.